Precision mechanical workshop

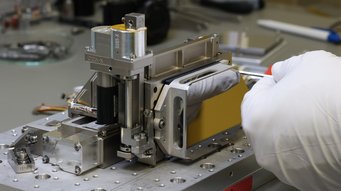

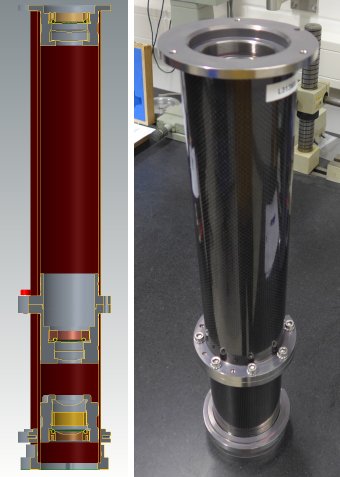

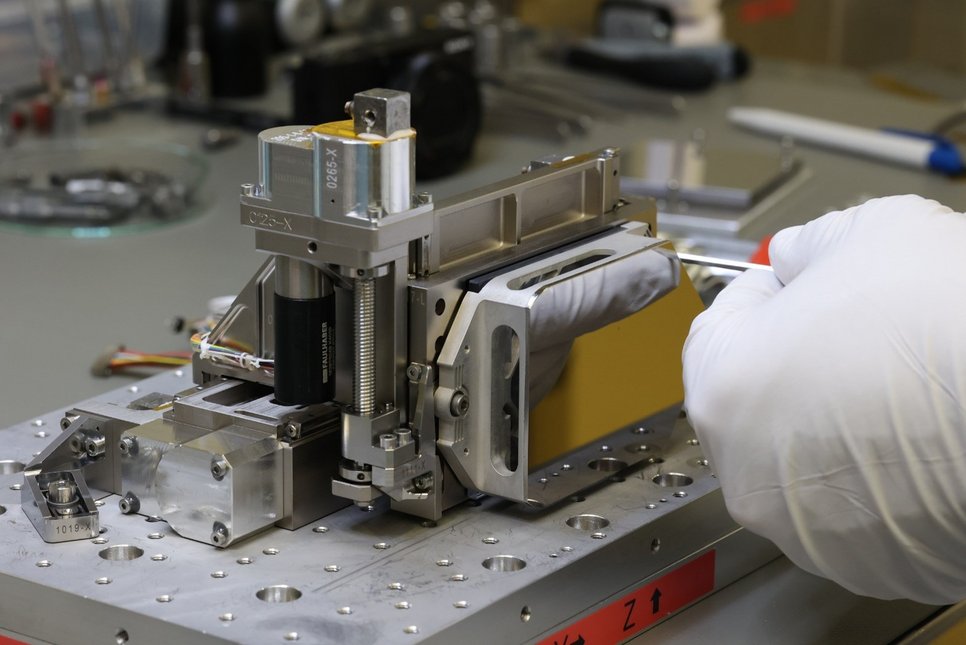

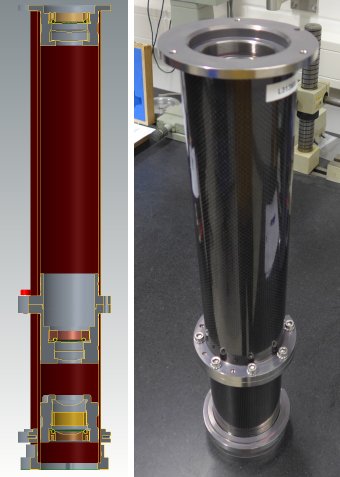

The requirements for the mechanical structures of astronomical instruments are daunting. Such structures must be extremely stable and allow for extremely precise placement of e.g. optical elements such as mirrors or lenses - image or signal quality can change drastically if a crucial element moves by as little as a millionth of a metre! For an instrument mounted on a telescope, such precise positioning must be maintained as the telescope tilts or rotates.

Space instruments pose a particular challenge: They need to withstand the accelerations and stresses of a rocket launch. They need to function reliably, as repairs after launch will be impossible. And they must function in a harsh, extremely cold environment where ordinary bearings with their reliance on lubricants cannot work.

MPIA's precision mechanical workshop supports our scientists by developing and building devices for astronomical research and teaching which cannot easily be purchased from external providers. The workshop contributes to feasibility experiments and helps to modify and repair existing scientific apparatus - often at short notice.

Our manufacturing processes make use of state-of-the-art technology. A workflow from 3d virtual models produced by CAD software from CNC machine tools, ensures quick turnaround, flexibility, and precision.

The department constantly offers apprenticeship positions and internships. More information about the apprenticeship program can be found here.